Heat exchangers for heat pumps are essential for energy efficiency and effective heating or cooling. This guide explains what a heat exchanger is, how it works in heat pump systems, and why it's important for both residential and commercial users.

Heat pumps have gained popularity due to their ability to transfer heat efficiently without generating it. One of the most crucial components enabling this process is the heat exchanger. For any heat pump system to perform optimally, a reliable and efficient heat exchanger must be in place.

A heat exchanger heat pump uses a component to transfer heat between two fluids—usually air and refrigerant or water and refrigerant. This transfer enables the heat pump to provide space heating, cooling, or domestic hot water. The exchanger doesn’t mix the fluids but allows heat to move between them.

Heat exchangers are fundamental to how heat pumps work. They allow a closed loop of refrigerant to absorb and release heat as needed, turning outdoor air or water into an efficient source of thermal energy. These devices are designed for optimal surface contact to enhance heat transfer and improve thermal efficiency.

Heat exchangers absorb heat from one area and move it to another. In heating mode, it takes heat from outdoor air or water and transfers it indoors. In cooling mode, the direction reverses. This efficient process uses refrigerants and specialized surfaces to move energy effectively.

The principle is based on thermodynamics—heat moves from warmer to cooler objects. The refrigerant acts as the carrier. When exposed to outdoor air or ground source temperatures, it absorbs heat and passes through the exchanger. That heat is then delivered inside the house or facility.

| Type | Application | Key Feature |

|---|---|---|

| Plate | Residential & commercial | High surface area for fast heat transfer |

| Microchannel | Compact units | Reduced refrigerant use |

| High-Efficiency Tank | Hot water systems | Efficient hot water storage |

| Double Wall Plate | Sanitary water | Safety and separation of fluids |

| Titanium | Swimming pool heat pump | Corrosion resistance |

| Shell and Tube | Commercial buildings | Durable under pressure |

| Coaxial | Small HVAC units | Cost-effective design |

* Overview of Common Heat Exchanger Types Used in Heat Pump Systems

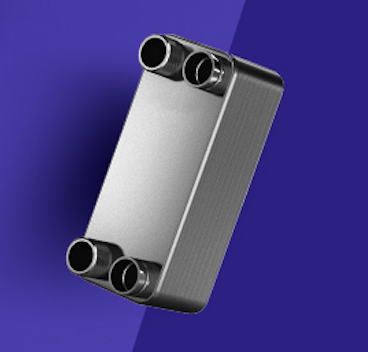

A plate heat exchanger consists of a series of thin metal plates that form multiple channels for heat transfer through a conductive medium.

Plate heat exchangers are commonly used in heating pump systems due to their compact structure and high heat transfer efficiency

A microchannel heat exchanger is made up of multiple small channels, utilizing the high surface area for efficient heat transfer.

This type of heat exchanger is widely used in all-in-one heat pump water heaters for its high heat transfer performance and compact design.

A high-efficiency tank is a specially designed heat exchanger known for its superior heat transfer capabilities.

High-efficiency tanks are typically used in split system heat pump water heaters due to their excellent heat transfer performance and reliability.

A double wall plate heat exchanger features a dual-layer design, enhancing safety and heat transfer efficiency.

This type of heat exchanger is uniquely suited for Australian heat pump water heaters, meeting specific regional requirements.

A titanium heat exchanger is made from corrosion-resistant titanium, designed for use in high-corrosion environments.

Titanium heat exchangers are widely used in pool heat pumps for their exceptional corrosion resistance.

A shell and tube heat exchanger consists of a shell (outer casing) and multiple tubes inside, where fluids flow through and around the tubes for heat exchange.

Shell and tube heat exchangers are suitable for commercial heat pump systems due to their high-pressure tolerance and efficient heat transfer.

A coaxial heat exchanger is made of concentric inner and outer tubes, transferring heat through the wall between the tubes.

Coaxial heat exchangers are commonly used in commercial heat pumps for their simple structure and efficient heat transfer capabilities.

Heat pump efficiency relies heavily on the exchanger. A well-designed unit maximizes surface area and minimizes resistance, improving energy use. Users benefit from lower utility bills and better performance.

When looking at different systems, it’s important to compare Seasonal Coefficient of Performance (SCOP) ratings. Higher SCOP values generally indicate that the exchanger operates with greater efficiency throughout the year.

Regular checks help avoid costly issues. Signs you may need maintenance include unusual noise, poor airflow, high energy bills, and visible corrosion.

Regular maintenance also helps improve indoor air quality and prolong system life. Replacing clogged or corroded heat exchangers early can prevent system-wide failures and avoid high replacement costs.

A luxury resort located in southern Spain faced ongoing challenges with maintaining stable water temperatures in its large outdoor swimming pool.

Traditional heating methods, including electric resistance heaters, were not only energy-intensive but also prone to corrosion due to exposure to chlorinated water.

In 2023, the facility upgraded to a titanium heat exchanger integrated within a high-efficiency pool pool heater system.

The titanium exchanger (heat exchanger for swimming pool heat pump) was chosen specifically for its excellent resistance to corrosion and its long service life. After just six months, the resort reported a 35% reduction in energy bills and a noticeable improvement in water temperature consistency. The maintenance team also noted fewer service interruptions and lower repair costs compared to their old system. As a result, the resort decided to implement the same system across its other aquatic facilities, including jacuzzis and indoor spa pools.

A five-story commercial office complex in northern Germany was operating with an aging boiler-based heating system that was inefficient and expensive to maintain. In 2022, the property management company partnered with SolarEast to retrofit the building’s HVAC system with a modern a modern heat exchanger in commercial heat pumps configuration, using shell-and-tube exchangers for both heating and cooling.

The upgrade significantly improved energy efficiency. Energy audits conducted post-installation showed a 20% reduction in electricity use and a 15% decrease in annual maintenance costs. Employees reported more consistent indoor climate control throughout the building, particularly during peak winter months. The new system also qualified for a government incentive program, covering nearly 30% of the installation cost due to its high energy-efficiency rating.

In a suburban neighborhood near Munich, a family living in a 2,000 sq. ft. detached home faced high winter utility bills and uneven heating. They replaced their outdated unit with a heat pump using a water-refrigerant heat exchanger, chosen for its performance in cold climates.

Within one heating season, the household recorded a 28% drop in monthly energy costs and reported a much more comfortable indoor environment. The exchanger’s ability to maintain efficiency even during freezing temperatures made it ideal for German winters. The family also appreciated the quiet operation of the system and the availability of smart controls for better temperature management.

Encouraged by the results, several neighbors consulted the same installer, leading to a mini local movement toward energy-efficient upgrades.

High-efficiency exchangers reduce greenhouse gas emissions and save money. Businesses benefit from improved ROI and compliance with environmental regulations.

High-Efficiency Heat Exchangers For eco-conscious businesses, switching to a green heat pump system with efficient heat exchangers is a step toward carbon neutrality. Many governments offer rebates or grants for installations meeting energy standards.

Choosing the right heat exchanger is essential to ensure optimal performance, energy savings, and system longevity. With so many options available, it’s important to evaluate both your current system requirements and your long-term energy goals.

First, identify your heat pump’s application: Is it for residential space heating, a water heater, a commercial building, or a swimming pool? Each use case has specific demands. For example, a domestic hot water system might benefit most from a high-efficiency tank or plate exchanger, while larger-scale buildings often require shell and tube models.

Next, consider your local climate. In colder regions, choosing a design that maintains high heat pump heat exchanger efficiency during low temperatures is vital. Water-refrigerant heat exchangers perform well in these conditions, offering consistent heat transfer even in sub-zero environments.

Materials also matter. If you're working in corrosive environments, like saltwater pools or coastal regions, titanium heat exchangers are ideal. On the other hand, brazed plate heat exchangers are more suitable for compact residential HVAC systems due to their small footprint and high efficiency.

Budget is a factor, but long-term ROI should guide the final decision. In this context, the best heat exchangers for heat pumps are not always the cheapest—they are the ones that provide the most energy savings, longest lifespan, and lowest maintenance over time. Consulting with an expert can help you balance upfront costs with performance expectations.

SolarEast offers customized OEM solutions, helping clients select the best fit for their heating or cooling systems with scalable options that adapt to future needs.

A: Plate and coaxial exchangers are popular due to their size and efficiency.

A: Typically 10–20 years, depending on maintenance and water quality.

A: Yes. New designs greatly improve heat pump operation.

A: Shell and tube exchangers perform well due to their durability and performance under high loads.

Understanding heat exchangers for heat pumps empowers you to make smarter decisions about your heating and cooling systems. With the right heat exchanger in place, you can significantly improve energy efficiency, reduce maintenance costs, and achieve a more consistent indoor climate year-round.

For those looking to dive deeper into advanced technologies, the U.S. Department of Energy has published a comprehensive technical report titled Heat Exchanger Solutions for Low-GWP Refrigerants. This resource explores cutting-edge designs and the importance of pairing heat exchangers with environmentally friendly refrigerants. You can download the full PDF here.

At SolarEast, we understand that every application is unique—whether you're heating a family home, supplying hot water to a hotel, or managing climate control for a commercial building. That’s why we don’t believe in one-size-fits-all. Instead, we offer OEM-ready systems featuring the best heat exchangers for heat pumps, carefully selected based on your system needs, climate conditions, and energy-saving goals.

Our engineering team works closely with partners to deliver tailor-made heat exchanger solutions that align with your performance expectations and local regulations. Whether you require corrosion-resistant titanium exchangers, compact brazed plate units, or shell-and-tube designs for industrial loads—we help you find the right fit.

Ready to upgrade your heat pump system with the ideal heat exchanger?

Contact SolarEast today and let our experts recommend the most efficient, durable, and cost-effective solution for your project.