R290 refrigerant is a natural hydrocarbon gas, also known as propane, with the chemical formula C₃H₈. It is gaining popularity as an environmentally friendly alternative to synthetic refrigerants in residential and commercial air source heat pump systems. Unlike high-GWP fluorinated gases, R290 has a Global Warming Potential (GWP) of just 3 and an Ozone Depletion Potential (ODP) of zero, making it compliant with the latest climate regulations in Europe and other global regions.

Due to its excellent heat transfer performance and low viscosity, R290 can significantly improve the energy efficiency of HVAC systems. It is particularly well-suited for air to water heat pump applications in both domestic and commercial buildings. In addition, its availability and low cost contribute to its appeal among manufacturers and installers.

However, being a hydrocarbon, R290 is highly flammable and categorized as an A3 refrigerant. This raises concerns about propane refrigerant dangers, especially in cases of poor ventilation, improper installation, or accidental leakage. Therefore, systems using R290 must be equipped with proper safety devices such as R290 leak sensors and must follow strict installation standards to ensure safe operation.Climate Weeks Return in 2025

When selecting a refrigerant for a modern heat pump system, understanding the difference between R32 vs R290 is essential. Both refrigerants are widely used in residential and light commercial HVAC systems, but they differ significantly in environmental impact, efficiency, safety, and future adaptability.

2.1 Environmental Impact:

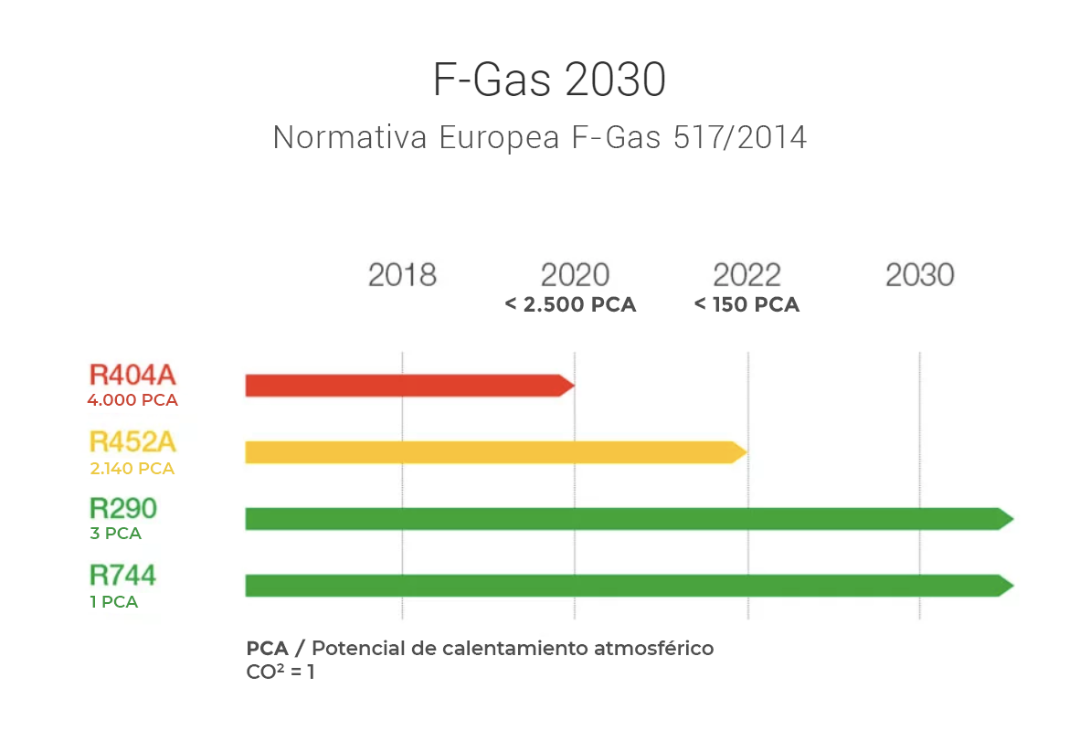

The most noticeable difference is their Global Warming Potential. R290 refrigerant has a GWP of just 3, while R32 stands at 675. This makes R290 a low GWP refrigerant, more compliant with current and upcoming climate regulations such as the EU F-Gas Phase-down and the Kigali Amendment to the Montreal Protocol. R290 is also classified as a natural refrigerant, while R32 is a synthetic fluorinated gas.

2.2 Safety Considerations:

In terms of safety, R290 is categorized as A3 — highly flammable. R32, while flammable too, is rated A2L, which means it is mildly flammable but less hazardous than propane. The propane refrigerant dangers associated with R290 must be mitigated through strict system design standards, R290 refrigerant leak prevention technologies, and installation by certified technicians.

| Feature | R290 Refrigerant | R32 Refrigerant |

|---|---|---|

| GWP ≈ 3 | GWP ≈ 675 (Synthetic HFC) |

| A3 – Highly flammable | A2L – Mildly flammable |

| In low-temperature applications | In high-load systems |

| Low | Moderate |

* R32 vs R290 diffrent discharge

2.3 Efficiency and Application

Both refrigerants offer excellent heat transfer performance, but R290 tends to perform better in systems like air to water heat pumps, especially in cold climate conditions. R32 is often used in split-type air conditioners and high-capacity commercial units. R290 is increasingly favored in compact residential heat pumps where eco-label compliance and energy efficiency are priorities.

2.4 Cost and Market Trend

R290 is generally cheaper and more readily available. Many manufacturers are transitioning towards R290 due to pressure from sustainability standards and consumer demand for green technologies.

In summary, while both refrigerants have their advantages, R290 is emerging as a strong long-term solution——provided its flammability risks are carefully managed.

R290 refrigerant offers a number of compelling benefits, making it a top choice for eco-conscious HVAC manufacturers and installers. Its strengths are especially apparent in modern air to water heat pump systems, where energy efficiency and sustainability are key.

| Low GWP |

R290 has a GWP of just 3, one of the lowest among all commercially used refrigerants. As a natural refrigerant, it complies with current and future environmental regulations, including the EU's F-Gas Phase-down and the Kigali Amendment. |

| High Energy Efficiency |

Due to its superior heat transfer properties and favorable thermodynamic characteristics, R290 enables better system performance, especially in cold climates. Units using R290 often achieve higher SCOP and COP values, translating into real energy cost savings. |

| Compatibility with Green HVAC Technologies |

R290 is well-suited for air source heat pump systems and other renewable-based heating solutions. Its use supports the transition to low-carbon buildings and net-zero emissions targets. |

| Cost-Effective and Widely Available |

As a propane-based gas, R290 is abundant and cost-efficient. It helps reduce long-term operating costs and offers stable supply in global markets. |

| Quiet Operation & Compact System Design |

Systems using R290 tend to run more quietly and can be designed more compactly, making them attractive for urban homes and indoor installations. |

| F-gas Limitation |

R32 will be restricted under F-Gas quotas after 2027 due to its GWP of 675, while R290, with a GWP of 3, remains fully exempt. |

Despite its advantages, R290 refrigerant also presents some limitations and risks that must be addressed through careful planning and professional management

| High Flammability Risk |

| R290 is classified as an A3 refrigerant, indicating high flammability. This leads to significant propane refrigerant dangers if not properly handled, particularly in enclosed spaces or poorly ventilated areas. |

| Strict Safety Requirements |

| To ensure safe use, systems must integrate features like R290 leak sensors, flameproof components, and venting strategies. Adherence to R290 refrigerant leak prevention protocols is not optional—it's mandatory. |

| Regulatory Restrictions on Charge Limits |

| Many national and international safety standards restrict the amount of R290 that can be used in certain applications, limiting the scalability of some systems unless sealed or compartmentalized design approaches are applied. |

| Specialized Installation and Maintenance |

| Only trained professionals should handle installation and servicing of R290 units. Lack of experience may lead to accidental release or even explosions. Manufacturers must offer clear documentation and after-sales technical support to prevent heat pump explosions and build user confidence. |

The primary danger associated with R290 refrigerant is its flammability. If there is a refrigerant leak and R290 comes into contact with a heat source or spark, it can ignite, resulting in an explosion risk. This makes it crucial to follow strict safety measures during installation, maintenance, and usage.

R290 Leak Sensors

R290 leak sensors detect refrigerant leaks in real-time, allowing technicians or homeowners to take immediate action to prevent the risk of fire. These sensors ensure early detection and timely intervention.

Microbubble Valves:

Microbubble valves regulate the pressure of the refrigerant inside the heat pump system, ensuring safe operation by preventing over-pressurization. These valves are critical in managing the R290 refrigerant charge safely.

For the blue skies of the future

R290 refrigerant is a natural gas with very low global warming potential. It meets the latest environmental rules in Europe and other regions. Compared to synthetic gases like R32, R290 is cleaner and more energy efficient. It works well in air to water heat pump systems.

Today, more heat pumps use R290. Why? Because safety features have improved. R290 leak sensors help detect leaks early. Microbubble valves remove air bubbles and reduce pressure issues. Together, they help prevent accidents.

As more countries phase out high-GWP refrigerants, low GWP refrigerants like R290 are the future. They are better for the environment and offer strong performance.

At SolarEast, we focus on safe, smart R290 systems. Our products follow global standards and work well in many homes and projects.