Blogs

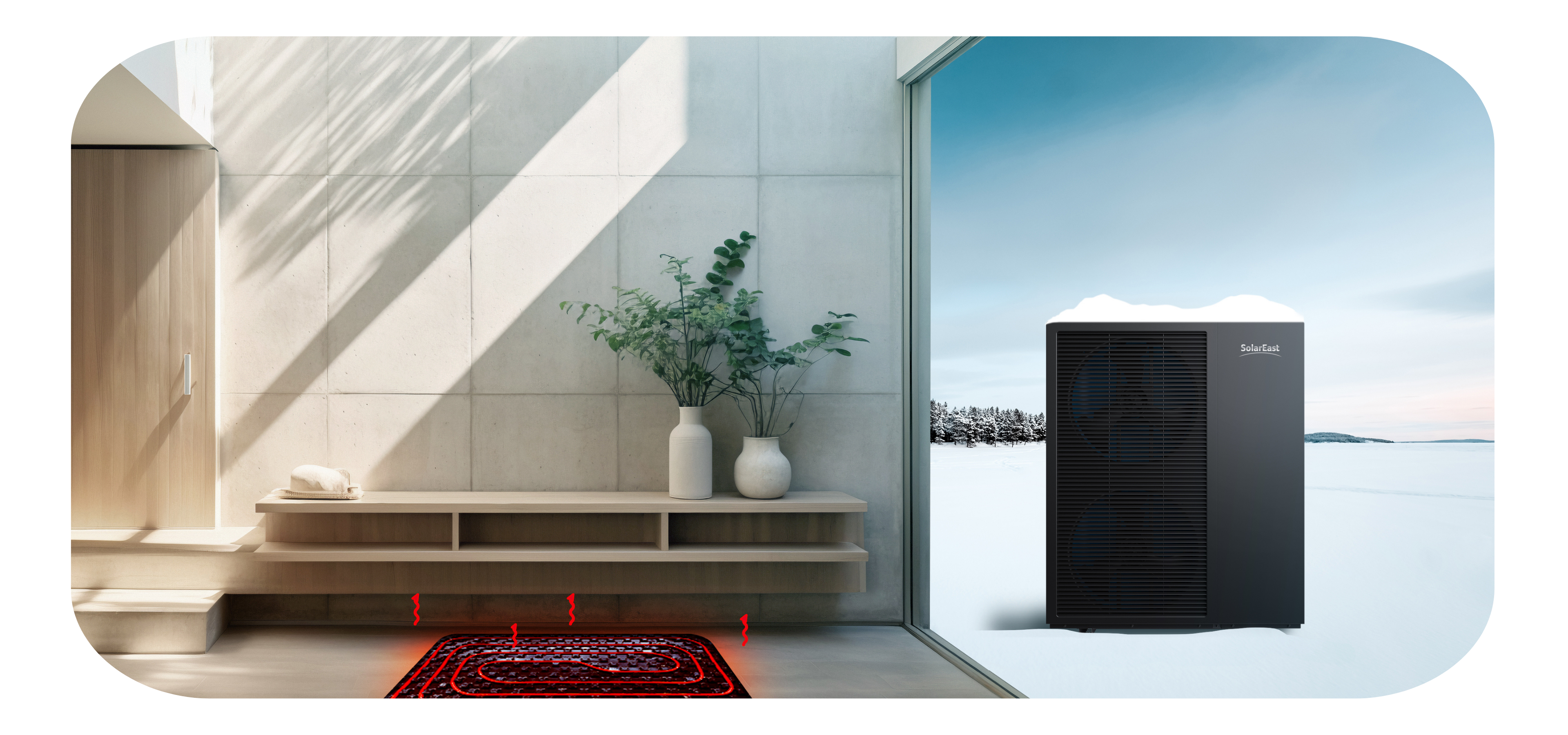

Choosing the right heating solution is essential for achieving long-term comfort and efficiency. Heat pumps underfloor heating systems have become one of the most reliable options in modern homes and commercial projects. By combining the efficiency of an air-to-water heat pump with the consistent warmth of a radiant floor heating system, homeowners can enjoy truly energy-efficient heating while significantly reducing carbon emissions. This guide explores how an underfloor heating system works with heat pumps, the benefits of adopting a heat pumps underfloor heating solution, and the key factors to consider before installation.

A Nordic Homeowner’s Story: Choosing the Best Heat Pump Against the Cold

How Heat Pumps Work with Underfloor Heating

Heat pump + underfloor heating setup works by transferring energy from the outdoor air into your home through an air to water heat pump. Instead of producing heat by burning fuel, the system extracts renewable energy and circulates it through warm water pipes embedded in the floor. This creates a large radiant surface, commonly known as radiant floor heating, which distributes warmth evenly across the entire room.

Because the water used in a heat pump-driven floor heating system only needs to reach relatively low flow temperatures (usually 30–40°C), modern hydronic heating solutions operate at their highest efficiency. This makes the combination one of the most effective methods for delivering energy efficient heating, ensuring both comfort and reduced running costs. Unlike traditional radiators, which deliver heat in concentrated spots, floor heating provides a consistent and gentle warmth that enhances indoor comfort in modern homes.

This heating combination system provides clear advantages compared with traditional heating methods such as gas boilers or radiator units. By integrating an air to water heat pump with an underfloor heating system, this approach ensures energy efficient heating and improved comfort, making it one of the most reliable alternatives to conventional solutions. Below are the key areas where heat pump-driven floor heating delivers superior performance.

Conventional boilers typically operate with water flow temperatures of 60–80°C, which limits efficiency. In contrast, a modern hydronic heating solution, especially when paired with an air to water heat pump, require only 30–40°C water temperatures. This lower range enables the system to deliver highly energy efficient heating, often achieving three to four times the efficiency of a standard boiler. Compared with traditional radiator setups, heat pump-based radiant heating ensures better performance while reducing operating costs.

System Type | Water Flow Temperature | Typical Efficiency | Running Cost Trend |

Gas Boiler + Radiator | 60–80°C | 85–92% | High |

Heat Pump + Underfloor | 30–40°C | 300–400% (SCOP) | Low |

Traditional radiator systems often create uneven heat distribution, resulting in hot and cold spots within a room. In contrast, heat pumps integrated floor heating

systems use radiant floor heating to spread warmth evenly across the entire surface, creating a steady and balanced indoor climate. This not only improves comfort but also reduces the need for high air circulation, making a low-temperature heating solution a superior alternative to conventional radiator-based heating.

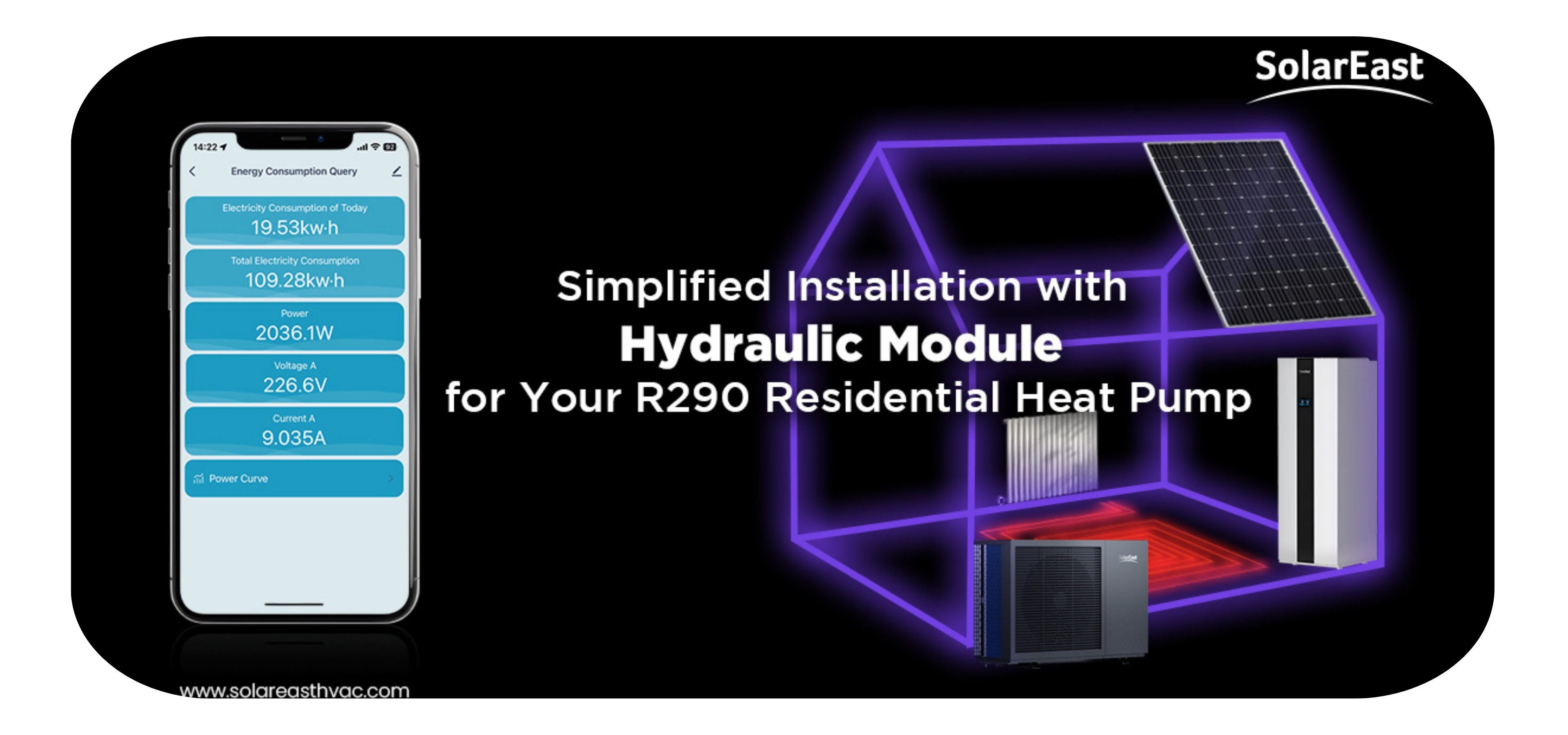

Low-temperature heating heat pump solution supports low-carbon living. Unlike traditional fossil fuel boilers, it produces significantly fewer CO₂ emissions while delivering reliable energy efficient heating. In addition, this heating combination can be integrated with renewable sources such as photovoltaic panels, making it a sustainable solution that aligns with modern environmental regulations and long-term climate goals.

Modern hydronic heating solutions are fully compatible with advanced thermostats and zoning controls, allowing precise temperature management across different rooms or floors. This integration enhances comfort and ensures energy efficient heating, offering greater flexibility compared to conventional single-zone boiler systems. As a result, this heating combination provides both smarter control and higher overall efficiency.

When assessing heating options for both residential and commercial applications, the contrast between low-temperature heating solution and traditional gas boilers becomes particularly significant. While boilers rely on high water flow temperatures and fossil fuels, low-temperature heating solution delivers energy efficient heating at lower operating costs with reduced carbon emissions. Key differences between the two solutions are summarized in the table below:

Category | Gas Boiler + Radiator | Heat Pump + Underfloor Heating |

Water Flow Temp. | 60–80 °C | 30–40 °C |

Efficiency | 85–92% (combustion efficiency) | 300–400% (SCOP/COP) |

Energy Source | Natural gas / fossil fuel | Renewable electricity + ambient air |

CO₂ Emissions | Higher | Significantly lower (depends on grid) |

Running Costs | Higher, volatile | Lower, more stable |

Integration | Limited | Compatible with solar PV, IoT, zoning |

Regulatory Outlook | Being phased out in EU | Supported by subsidies and mandates |

Efficiency: The Energy Saving Trust states that heat pumps deliver three to four times the heat for each unit of electricity consumed (i.e., 300–400% efficiency), compared to an A-rated gas boiler that achieves up to ~90% efficiency .

CO₂ Reductions: According to the International Energy Agency (IEA), heat pumps reduce greenhouse gas emissions by at least 20%, even when powered by emissions-intensive electricity—this savings can rise up to 80% in countries with cleaner energy mixes .

Policy Trends: The EU is advancing regulations under REPowerEU and the Ecodesign framework to phase out standalone fossil fuel boilers by 2029, reinforcing the shift toward cleaner heating technologies.

Installing a heat pump-driven floor heating system requires careful planning to guarantee both long-term efficiency and comfort. Compared with conventional radiator systems,

modern hydronic heating solution projects involve specific technical requirements that must be addressed during both the design and installation stages. Proper integration witha

low-temperature heating solution ensures reliable performance and truly energy efficient heating over decades of operation.

New-build projects: These are ideal for heating combination, as pipework can be embedded directly into the concrete slab.

Retrofit projects: Often require low-profile floor panels or raised systems to reduce the impact on floor height.

Residential vs. commercial: While smaller homes typically use a single unit, larger projects may require multiple air-to-water heat pumps in cascade to maintain performance.

Proper pipe spacing and flow rates are essential for uniform heat distribution.

Supply temperatures should remain between 30–40 °C to ensure high efficiency with radiant floor heating.

Hydraulic balancing is critical to avoid hot or cold zones within the property.

A modern hydronic heating solution can be integrated with smart thermostats and zoning controls.

Independent room or floor-level control helps prevent energy waste and increases comfort.

For commercial buildings, integration with Building Management Systems (BMS) or IoT platforms allows advanced monitoring and optimization.

Heat pumps underfloor heating systems generally require less day-to-day maintenance compared to traditional radiators. However, regular checks for pressure levels, water flow, and control calibration are essential to keep the system performing at its best.

For B2B projects, reliable after-sales service from the heat pump manufacturer plays a critical role in ensuring long-term stability. For example, in one recent commercial project in Northern Europe, a 12 kW SolarEast heat pumps underfloor heating system was installed in a medium-sized office building. During its first winter, the system operated efficiently at –10 °C outdoor conditions, but a minor issue with the manifold balancing required quick intervention. Thanks to remote monitoring and timely support from the SolarEast technical team, the adjustment was made within 24 hours, ensuring uninterrupted heating for the entire facility.

This case highlights how SolarEast not only delivers high-performance products but also provides dependable after-sales support, building long-term trust with global B2B partners.

Older homes are common across Northern Europe — and so are heating problems.

This real-life project from southern Sweden shows how one household addressed poor insulation and noise concerns during a winter heat pump retrofit, without overengineering the system.

The house is a two-storey detached home built in the early 1990s, with a heated area of around 180 m².

Structurally sound, but far from modern energy standards.

Before the retrofit, the home relied on a gas boiler with radiators. As winters became colder and energy prices rose, the system began to show clear limits.

The biggest challenge was not heating capacity — it was heat loss.

Like many homes from that period, the building had:

Limited wall and roof insulation

Thermal losses around windows and junctions

Fast indoor temperature drop during winter nights

As a result, the heating system had to run for long hours just to maintain comfort.

“The house was warm for a while,” the homeowner explains,

“but it never stayed warm for long.”

Noise turned out to be just as important.

The outdoor unit had to be installed close to the façade, less than 4 meters from the living room wall — a very common situation in European residential areas.

In winter, heating systems run day and night. Any vibration or sudden sound changes quickly become noticeable indoors and can affect neighbors.

Quiet operation was not a bonus. It was a requirement.

Because insulation levels were limited, the system needed enough capacity to:

Handle peak demand during cold spells

Avoid constant high-load operation

Reduce frequent start-stop cycles

After evaluation, an 18 kW SolarEast Plus Series air-to-water heat pump was selected.

The choice was not about oversizing — it was about stability under real conditions.

One design detail stood out during operation:

The independent compressor chamber used in the Plus Series.

By physically isolating the compressor from the main cabinet, vibration transfer was significantly reduced. In practice, this meant:

No noticeable low-frequency vibration indoors

Smooth start-up without noise spikes

Stable sound levels, even during continuous winter operation

“After a few cold nights, we stopped noticing the system,”

the homeowner says.

“That’s when we knew it was working properly.”

After the first full heating season, the results were clear:

Indoor temperatures became more even, especially on the ground floor

Night-time comfort improved due to lower noise

Energy use became predictable and manageable

The system ran quietly in the background

The house itself did not change — but how it felt to live in it did.

This was not a new build or a perfect test case.

It was a real retrofit in an older Nordic home, with:

Average insulation

Limited outdoor installation space

Long winter operating hours

The key takeaway is simple:

In older European homes, a heat pump does not need to be extreme —

it needs to be quiet, stable, and forgiving.

For this household, the SolarEast Plus Series delivered exactly that.

Accurate heat load calculation is the foundation of properly sizing a low-temperature heating solution. Oversizing increases upfront costs and reduces efficiency, while undersizing fails to deliver sufficient comfort. For both residential and commercial projects, correct sizing ensures that heat pumps underfloor heating deliver reliable performance and long-term energy efficient heating.

Suggested Capacity Guidelines

Building Type | Typical Area (m²) | Recommended Heat Pump Capacity | Notes |

Small Residential Home | <150 m² | 4–6 kW | Single heat pump underfloor heating system usually sufficient |

Medium Residential Home | 150–250 m² | 7–10 kW | Zoning may be required for optimal comfort |

Large Residential / Villa | 250–400 m² | 10–16 kW | Consider multiple units in cascade |

Commercial Project | >400 m² | 16 kW+ (cascade system) | Detailed load calculation and often multiple air to water heat pumps required |

In mild climates, standard models are usually sufficient to meet demand.

In colder regions, low-temperature models or units with enhanced vapor injection (EVI) technology should be selected to maintain efficiency at sub-zero outdoor conditions.

Always review the manufacturer's performance data at the local design outdoor temperature.

Climate-Based Selection

Climate Type | Typical Winter Temp | Recommended Solution |

Mild Climate | Above 0 °C | Standard air to water heat pump |

Cold Climate | -5 °C to -15 °C | Low-temperature model with optimized SCOP |

Extreme Cold | Below -15 °C | EVI or cascade system for stable output |

Ensure the system is compatible with low water flow temperatures (30–40 °C) to achieve energy efficient heating.

Proper integration with radiant floor heating ensures even distribution and stable comfort.

Smart controls and zoning should be included for flexibility and long-term savings.

Look for certifications such as CE, ErP, Keymark, and MCS, which validate performance and safety.

Certified systems often qualify for government subsidies and incentives, reducing total project costs.

For OEM/ODM projects, long-term manufacturer support and service capability should also be evaluated.

When evaluating a modern hydronic heating solution, two of the most common questions are: How much will the installation cost? and How long will it take? Both depend on building type, project size, and system complexity.

The total cost is influenced by:

System size and capacity: Larger buildings require higher-capacity air-to-water heat pumps and more pipework.

New-build vs retrofit: New construction is more cost-effective, as pipes can be embedded directly into the concrete slab. Retrofitting usually adds 15–30% extra cost for floor preparation and insulation upgrades.

Controls and accessories: Smart thermostats and zoning increase upfront costs but improve long-term savings.

Local market: Labor rates and available subsidies vary significantly across countries.

Typical Installation Cost Ranges in Europe

Project Type | New-build (avg. cost incl. equipment & installation) | Retrofit (avg. cost incl. equipment & installation) | Notes |

Small Residential (<150 m²) | €8,000 – €12,000 | €9,500 – €14,000 | Usually one air to water heat pump with simple underfloor loop |

Medium Residential (150–250 m²) | €12,000 – €18,000 | €14,000 – €21,000 | Often includes zoning and smart controls |

Large Residential / Villa (250–400 m²) | €18,000 – €25,000+ | €21,000 – €30,000+ | May require multiple units in cascade |

Commercial Project (>400 m²) | Case-specific, often €30,000+ | Case-specific, usually higher | Requires engineering design and multiple units |

Data Reference:

Installer quotes from Germany and France (market survey data).

The duration of installation also depends on project scale and complexity:

Small residential projects: 3–5 working days, including pipe laying and commissioning.

Medium to large homes: 1–2 weeks, especially if zoning and smart controls are included.

Commercial projects: Can range from several weeks to months due to engineering requirements and multiple air to water heat pumps being installed in cascade.

Typical Installation Timelines

Project Type | New-build Duration | Retrofit Duration | Notes |

Small Residential (<150 m²) | 3–5 days | 5–7 days | Simple installation, retrofit requires extra floor prep |

Medium Residential (150–250 m²) | 1–2 weeks | 2–3 weeks | Zoning and smart controls add time |

Large Residential / Villa (250–400 m²) | 2–3 weeks | 3–4 weeks | More complex pipe networks |

Commercial Project (>400 m²) | Several weeks–months | Several weeks–months | Requires professional engineering design and testing |

Are heat pumps compatible with all types of underfloor heating systems?

Yes, modern air to water heat pumps are designed to work with both wet underfloor heating systems (water-based pipes) and, in some cases, hybrid solutions. However, they are not suitable for traditional electric underfloor heating systems, which operate at much higher temperatures.

How efficient is a heat pump when combined with underfloor heating?

Because radiant floor heating operates at low water flow temperatures (30–40 °C), a heat pump can achieve 300–400% efficiency (SCOP). This is significantly higher than a gas boiler system, which typically operates at 85–92% efficiency.

What is the average lifespan of a heat pump underfloor heating system?

A well-installed heat pump underfloor heating system can last 15–20 years with regular maintenance. The underfloor pipework itself often lasts 40–50 years, meaning only the heat pump unit may need replacement during the system’s lifetime.

Do heat pumps with underfloor heating work well in cold climates?

Yes. With the right model—such as units equipped with low-temperature operation or EVI (Enhanced Vapor Injection) technology—air to water heat pumps can perform efficiently even at outdoor temperatures below –15 °C.

How much maintenance does a heat pump underfloor heating system require?

Maintenance is minimal compared to boiler systems. The main tasks include checking water pressure, ensuring filters and manifolds are clean, and scheduling an annual professional inspection of the air to water heat pump.

Can heat pumps underfloor heating systems be retrofitted into existing buildings?

Yes. Heat pumps underfloor heating can be installed in both new-build and retrofit projects. For existing homes, low-profile underfloor heating panels are often used to minimize floor height changes. Although retrofit projects may require higher upfront investment compared with new-builds, they still deliver long-term benefits such as lower running costs, improved comfort, and sustainable energy efficient heating.

How long does a heat pumps underfloor heating system last?

A well-installed heat pumps underfloor heating system can last 20–25 years with minimal maintenance. The underfloor pipework itself is extremely durable, often lasting 50 years or more. Regular checks on the air to water heat pump ensure consistent energy efficient heating and long-term reliability.

Are heat pumps underfloor heating systems eligible for government incentives?

Yes. In many European countries, installing heat pumps underfloor heating qualifies for subsidies or tax credits under renewable energy and decarbonization programs. Incentives vary by country but can significantly reduce upfront investment, making energy efficient heating more affordable for homeowners and businesses.

Do heat pumps underfloor heating systems work in very cold climates?

Yes. Modern heat pumps underfloor heating systems are designed to operate efficiently even in freezing temperatures. With low-temperature or EVI (Enhanced Vapor Injection) air to water heat pumps, they can maintain reliable energy efficient heating even at –20 °C, making them suitable for Northern and Eastern European markets.

What flooring types are suitable for heat pumps underfloor heating?

Heat pumps underfloor heating systems are compatible with many floor coverings, including tile, stone, engineered wood, and vinyl. Materials with good thermal conductivity deliver the best results, ensuring quick heat transfer and improved efficiency. Carpet can also be used, but low-tog types are recommended to maintain energy efficient heating performance.

In conclusion, heat pumps underfloor heating systems offer a smart combination of comfort, energy efficiency, and long-term sustainability. Whether for new-builds or retrofit projects, they represent a future-proof investment that outperforms traditional boilers.

For readers who want to dive deeper into cold-weather performance, check out our guide:

Do Air-to-Water Heat Pumps Really Work in Cold Climates?

With SolarEast heat pumps, you get not only high-performance products but also reliable after-sales service and global project experience. Contact our team today to explore the right solution for your next project.