Blogs

How to Fix Banging Pipes / Water Hammer Video

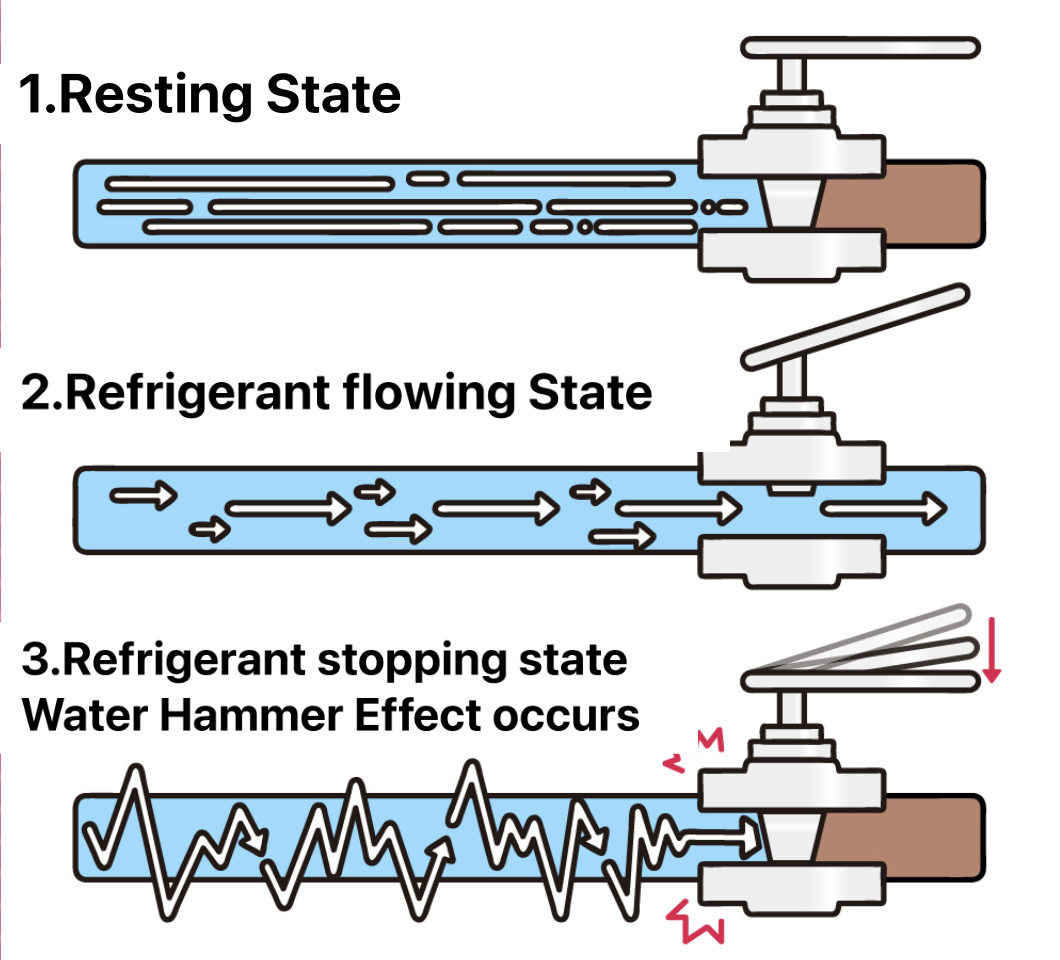

A sudden change in water flow can cause a hydraulic shock, also known as the water hammer effect. This issue commonly occurs in heat pump systems, leading to loud bangs, vibrations, and potential damage to pipes and valves. It can also increase long-term maintenance costs and reduce the efficiency of a plumbing system.

Understanding how to prevent water hammering in heat pumps is crucial. This guide explains its causes, risks, and how to protect your system using water hammer arrestors and optimized piping solutions.

EPA Recommendations for Water Flow Management

The effects of water hammer occur when flowing water suddenly stops or changes direction. This creates a pressure surge that can weaken piping systems, leading to damage over time. This phenomenon is common in water systems, HVAC equipment, and washing machines.

Signs of Water Hammer in a Heat Pump System

Loud bangs in the pipes when turning the system on or off

Sudden pressure spikes that shake the piping system

Visible pipe movement or damage over time

Increased maintenance costs due to failing components

Issues with high water pressure causing strain on the water system

Understanding what causes hydraulic shock is essential to implementing the right solutions.

When a water valve shuts suddenly, it stops water movement abruptly, causing a shockwave. The effects of water hammer are more severe when the system lacks pressure control mechanisms.

Excessive pressure in a plumbing system can lead to instability. This is common in domestic hot water heat pump heat exchangers and commercial HVAC systems. High water pressure can also accelerate pipe wear and increase energy consumption.

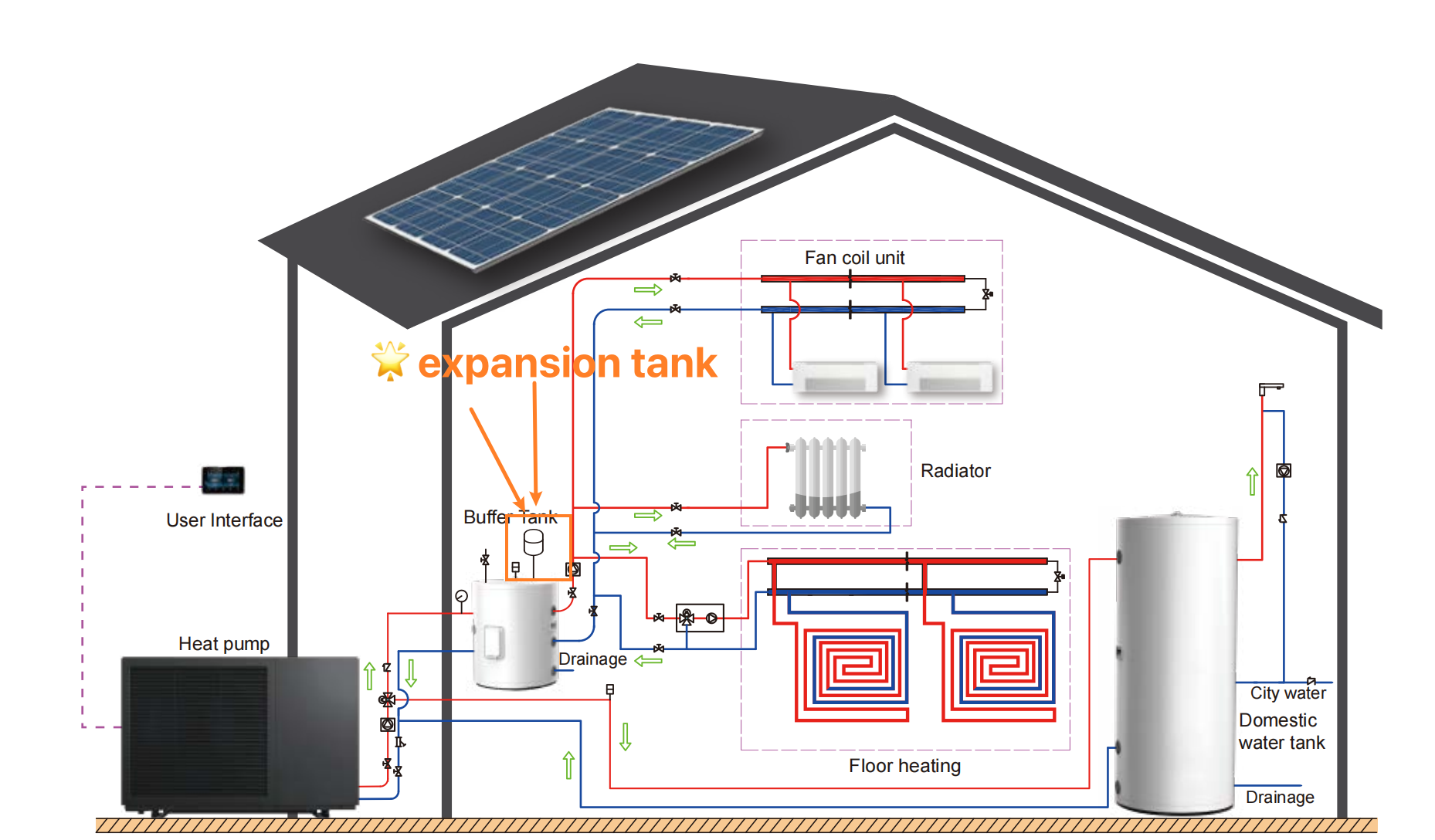

A piping system without air chambers or expansion tanks lacks the ability to absorb pressure spikes, increasing the severity of water flow issues.

If a heat pump system shuts down abruptly, it causes a rapid pressure fluctuation that leads to loud noises and vibration. Suddenly stopping a pump without pressure relief measures can worsen the effects of water hammer.

Preventing pressure surges in heat pump systems involves design improvements and regular maintenance.

A water hammer arrestor helps absorb sudden pressure spikes, preventing damage and reducing loud bangs in the pipes. This is particularly important for swimming pool heat pump heat exchangers.

Ensuring that the piping system is properly sized and has gradual bends reduces the risk of hydraulic shock. A well-designed plumbing system minimizes high water pressure issues and prevents suddenly stopping effects.

Slow-closing water valves prevent sudden flow stoppages, reducing the occurrence of hydraulic shock.

For commercial heat pump heat exchangers, regulating the flow rate can prevent excessive pressure buildup. Managing high water pressure in these systems ensures long-term efficiency.

Checking and servicing pumps, valves, and heat exchangers prevents failures that contribute to hydraulic shock in water systems. If valves close too quickly, maintenance can help adjust the system to avoid pressure spikes.

Selecting the right heat exchanger minimizes the impact of pressure fluctuations.

| Heat Exchanger Type | Best Application | Prevention of Hydraulic Shock |

|---|---|---|

| Plate Heat Exchanger | Domestic hot water heat pump systems | Compact design, stable flow control |

| Shell & Tube Heat Exchanger | Commercial HVAC systems | High durability, pressure resistance |

| Microchannel Heat Exchanger | Swimming pool heating systems | Efficient heat transfer, minimal turbulence |

Solareast provides high-quality heat exchangers designed to prevent hydraulic shock while improving energy efficiency and durability.

✅ Custom designs for space heater heat exchangers and commercial heat pump systems

✅ Long-term reliability with corrosion-resistant materials

✅ Optimized water flow control to reduce sudden stopping issues

✅ Reliable solutions for residential, commercial, and swimming pool heating

Experiencing plumbing system issues? Contact Solareast for the best heat pump heat exchangers!

ASHRAE Guidelines on Water Hammer

Uncontrolled pressure surges in heat pumps can cause serious inefficiencies and damage. Implementing preventive measures such as water hammer arrestors, optimized pipe layouts, and the right heat exchanger selection can significantly reduce the impact of hydraulic shock.

Need a long-term solution for preventing loud bangs and unstable water flow? Solareast’s innovative heat exchangers are built for system efficiency and stability.

It is a pressure surge caused by sudden water flow stoppage, leading to noise, vibrations, and possible damage.

Installing water hammer arrestors, using slow-closing water valves, and optimizing the piping system can prevent hydraulic shock.

Microchannel and shell & tube heat exchangers are ideal for reducing hydraulic shock and maintaining stable water flow.

Yes, repeated pressure surges can weaken pipes, damage heat exchangers, and lead to expensive repairs.

✔ Install a water hammer arrestor

✔ Use slow-closing water valves

✔ Optimize plumbing system design

✔ Maintain consistent flow rates in commercial heat pump systems